PRODUCTS

PRODUCTS SHOW

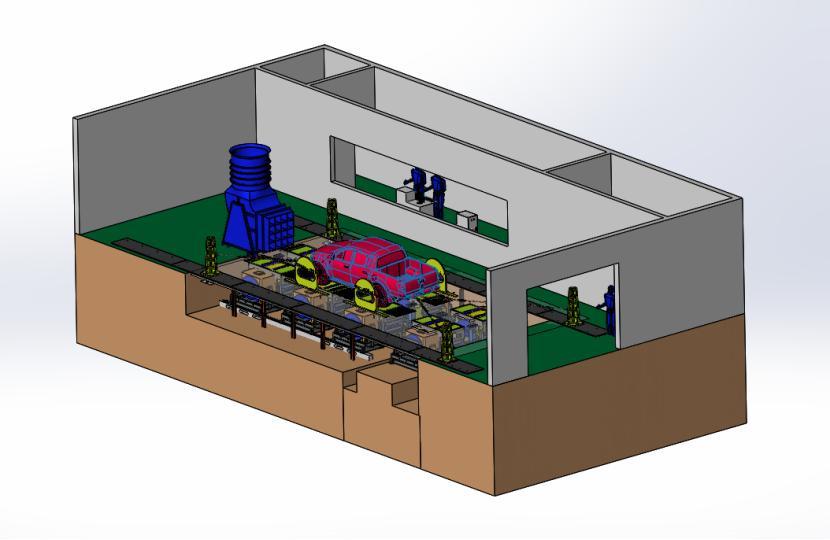

Integrated Performance Testing System for Electric Forklifts

The factory inspection of electric forklifts is a consistency inspection of the production line of forklifts, and is an important basis for scientific evaluation of forklift performance. This project develops an integrated testing system for the performance of electric forklifts in accordance with domestic and international standards (ISO-6292), which integrates various parameters such as weighing, maximum speed under no load/full load, braking distance under full load, and climbing ability of three/four wheel forklifts. Compared to the traditional method of using specialized ground runways and ramps for item by item testing, The use of a chassis dynamometer and loading device to simulate forklift testing conditions and integrate them with weighing units has significant advantages such as small footprint and high automation, which can effectively improve the detection efficiency of electric forklift related performance.

- System Advantages

- System Features

- System Characteristics111

- Main Technical Parameters

-

1) Drum diameter: 10” (254mm±0.25mm)

2) The width and interval of the drum: 500mm-500mm-500mm (500mm inside the drum and 1500mm outside)

3) Hub center distance: 420mm

4) The maximum test vehicle speed is not less than 20km/h;

5) Rated power of dynamometer: 45kw

6) Mechanism: motor bias structure, the motor can run in both directions, the dynamometer can run in two modes of speed and torque

7) Inertia simulation range: 500kg-3500kg -

Motor power: 30kW * 2/45kW * 2/56kW * 2

Structure: Motor bias

Roller size: 10 inches (254mm ± 0.254mm)

Max speed: ≥ 20km/h

Dynamometer overload capacity within 30 seconds: 130%

Inertia simulation range: 454kg-3500kg

Inertia simulation accuracy: ± 0.1% F.S

Inertia tracking response time: ≤ 100ms

Road simulation control response time: ≤ 100ms

Road load simulation accuracy: 1% or 9.8N;

Motor working efficiency: 92%

Cooling method of the dynamometer: forced air cooling

Keywords:

Message consultation